Preliminary design

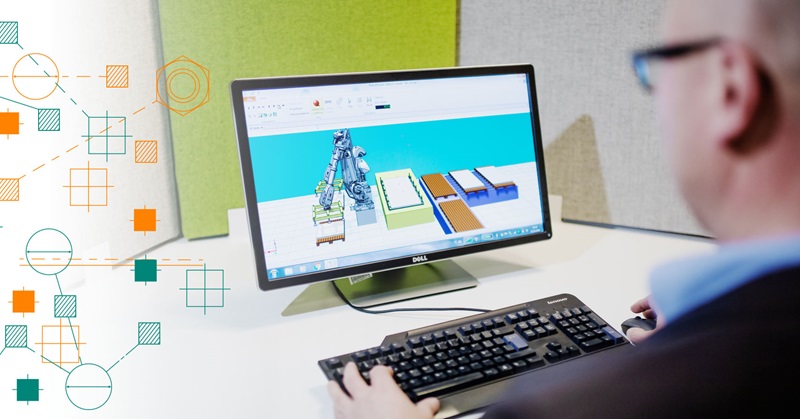

3D modelling in preliminary design and during the project

When performing preliminary design and also design during the project, we utilise 3D modelling. 3D modelling creates the preconditions for making a safe investment decision. The customer can buy just the preliminary design or the implementation of the entire system.

The objective of preliminary design is to chart the ways automation can be utilised in production when seeking the highest possible productivity. It may involve the entire factory’s production or a single production line.

Preliminary design utilises the most up-to-date programmes of the virtual world. We carry out this design and production simulation using 3D programmes, such as SolidWorks and RobotStudio. Preliminary design involves creating a virtual environment of the customer’s production, production lines and individual manufacturing processes for products.

During project implementation, the production line is visualised as a 3D model. After that, the functionality of the production line is simulated using RobotStudio. Simulation brings the whole production process to life: it shows a product’s journey through the manufacturing process and allows us to work out the robot’s technical limits. At the same time, we can make sure that the best equipment and technology for the purpose have been chosen. The aim of simulation during the project is to ensure that the entire production process runs efficiently. When the simulation is complete, the basic design for the automation of production is ready.

The advantages of 3D modelling:

- Preliminary design illustrates to the customer the various alternatives for the automation system. Virtual models not only make it easier to picture the different alternatives in practice, but also to examine the solutions from an economic point of view.

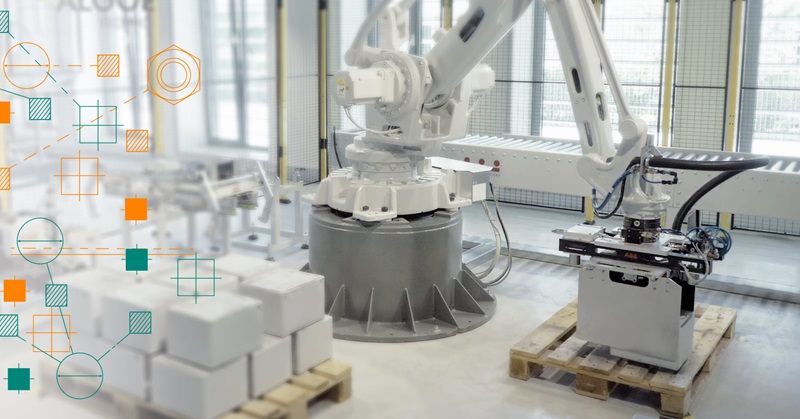

- Modelling helps us to design a solution that will work in real life. It helps in making decisions on the appropriate choices for equipment and robots. This also means that technical risks can already be eliminated in the design phase.

- Modelling provides a realistic picture of the space required for the system in the factory.

- The 3D models make it easy for everyone, not just the production experts, to immediately understand the way the cells and equipment will work.

- Using the 3D model, the customer can demonstrate in a graphic way the operation of the production line inside their own organisation. This helps the various parties involved inside the company to assess the effectiveness of the investment and its consequent production advantages and to make a well thought out decision.

- Modelling speeds up both decision making and system design.