CO-IAP

CO-IAP – Integrating automation into the operations control system.

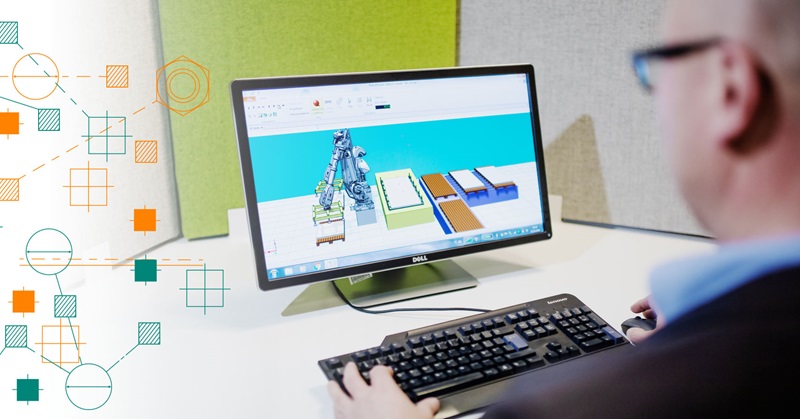

When the automation system is integrated into the operations control system it is essential that it produces the correct information at the correct time.

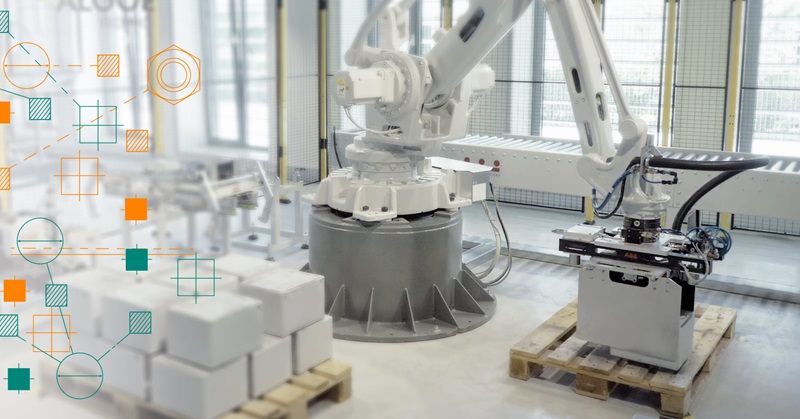

It produces excellent results in productivity monitoring. In addition, the system transfers essential information about quantities and the products manufactured and itemises by serial number more than 100 separate pieces of information per manufactured piece. At the same time, the pieces manufactured, their quantity and deductions from materials are recorded in the ERP system. In other words, the system automatically maintains the stock balance of both materials and completed products.

The best results are achieved when the integration is performed by the system supplier, who has in-depth knowledge of the entire process and the intricacies of data processing. One example of efficient data collection and management is the information collected under the serial number. When all the manufacturing data of a product is recorded – including the batch numbers of sub-components – it makes it considerably easier to trace the product later in case of defects or recalls. It also facilitates the recognition of copy products. The operations control system enters the serial number into the system and labels the product with it. The system collects all the data under this serial number and transfers this data to the customer’s operations control system.

The responsibility for the integration remains with the supplier. When the system supplier takes care of the integration, the customer has one less employee to pay. This operations model reduces the possibility of errors, speeds up the process and reduces the customer’s workload at the integration phase. It also guarantees considerable cost savings.